The following sample of business process documentation gives some idea of the style of document I produce. This is a single page showing three very simple processes. The full format is in a multi-page presentation, including indexes and detailed descriptions of roles.

The diagrams show the sort of information that is dynamically built during a Discovery Workshop. Participants can get a much better idea of the processes they are describing when shown this sort of presentation and will interact directly as the diagrams and supporting text is built. Much of the fine detail and tidying up is done outside of the workshop, but user familiarity is built as the process proceeds, making accuracy much easier to achieve.

You can navigate around this page by clicking on the links below to get to the three processes. Once there, click on the icons within each diagram to view the associated text and further diagram detail if available. (E.g. "Check Order" below.)

Inwards

Goods

Inwards

Goods

Overview:

Goods incoming from the supplier need to be thoroughly checked before being used

or placed on storage shelves. This process includes several steps where checking

is done for various aspects that may be a problem. If this checking is consistently

followed, problems when processing sales orders should not generally occur.

1. Process: Inwards Goods

Who can start this process?

Warehouse

Manager

Warehouse

Manager

Warehouse

Staff

Warehouse

Staff

Check

Order

Check

Order  Back

to flow

Back

to flow

Overview:

Shipment is checked against the documentation, which should be supplied with

the cartons as received from the supplier.

The number and condition of cartons is checked. The number of cartons

should be stated on the documentation.

Within each carton, all part numbers and quantities are checked against the

supplier’s documentation and original purchase order.

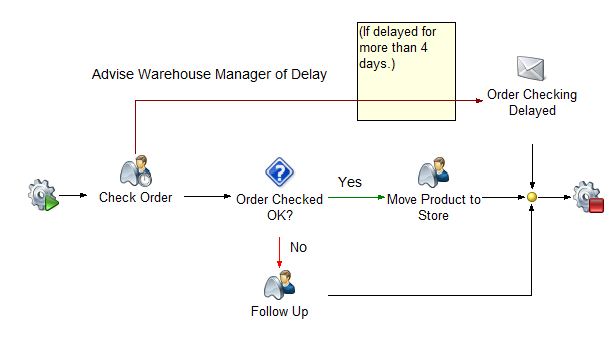

2. Process: Inwards Goods, Stage: Check Order

Warehouse

Manager

Warehouse

Manager

Warehouse

Staff

Warehouse

Staff

Advise Warehouse Manager of Delay.

Advise Warehouse Manager of Delay.

Warehouse

Manager

Warehouse

Manager

Advise Warehouse Manager of Delay.

Advise Warehouse Manager of Delay.

Check

Cartons (Manual)

Check

Cartons (Manual)

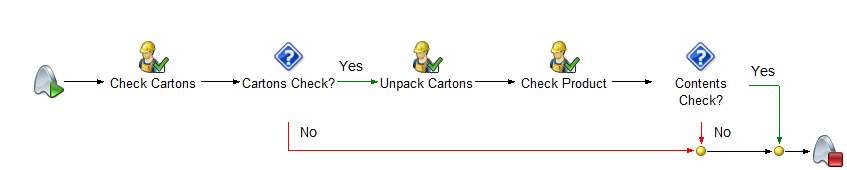

Procedure:

Check shipment against accompanying documentation, checking the number and

condition of cartons.

Cartons

Check? (Condition)

Cartons

Check? (Condition)

Procedure:

Has the correct number of cartons been delivered, in good condition?

Unpack

Cartons (Manual)

Unpack

Cartons (Manual)

Procedure:

Unpack all cartons to check contents. Keep contents together according

to carton number used by the supplier.

Check

Product (Manual)

Check

Product (Manual)

Procedure:

Within each carton, check part numbers and quantities against the supplier’s

documentation and original purchase order.

Contents

Check? (Condition)

Contents

Check? (Condition)

Procedure:

Shipment is checked against the documentation. The documentation is

packed in cartons as received from the supplier.

The number and condition of cartons is checked. The number of cartons

is stated on the documentation.

Within each carton, part numbers and quantities are checked against factory

documentation and the original purchase order.

Has the correct quantity of correct product for all products been supplied

by the supplier?

Order

Checking Delayed

Order

Checking Delayed Back to flow

Back to flow

Order

Checking Delayed (Send Email)

Order

Checking Delayed (Send Email)

Procedure:

If there is an unreasonable delay in checking incoming product, the Warehouse

Manager is advised.

This allows the resolution of any problems at Inwards Goods that are causing

delays.

Order

Checked OK? (Condition)

Order

Checked OK? (Condition)

Follow

Up

Follow

Up Back to

flow

Back to

flow

Warehouse

Manager

Warehouse

Manager

Follow

Up (Manual)

Follow

Up (Manual)

Procedure:

If any carton(s) are damaged, follow up with transport operator(s).

If any discrepancy in goods supplied is found, contact the supplier to resolve

the problem.

Move

Product to Store

Move

Product to Store Back to flow

Back to flow

Move

Product to Store (Manual)

Move

Product to Store (Manual)

Procedure:

Place all items on the correct shelf in the store as noted on the label.

Product

Return Requested

Product

Return Requested

Overview:

As much information as possible is obtained about why product is being returned before this return is authorised. This makes the handling of returned

goods simpler, and also enables factory originated faults to be reported to them

for correction.

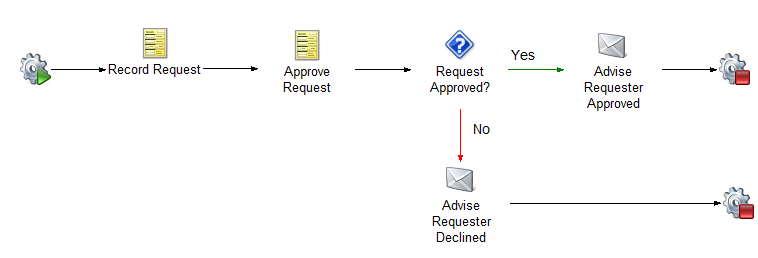

9. Process: Product Return Requested

Who can start this process?

Warehouse

Manager

Warehouse

Manager

Office

Staff

Office

Staff

Warehouse

Staff

Warehouse

Staff

Record

Request

Record

Request Back

to flow

Back

to flow

Office

Staff

Office

Staff

Warehouse

Manager

Warehouse

Manager

Warehouse

Staff

Warehouse

Staff

Return

of Goods Request(Worksheet)

Return

of Goods Request(Worksheet)

Procedure:

Enter all details relating to the request.

The more information available, the more likely the request will be approved.

The original sales order must be located and the order number entered.

Approve

Request

Approve

Request Back

to flow

Back

to flow

Management

Management

Warehouse

Manager

Warehouse

Manager

Approve

Request (Worksheet)

Approve

Request (Worksheet)

Procedure:

Review the information provided and either approve or decline.

Please add any comments and / or reasons for your approving / declining

the request.

Request

Approved? (Condition)

Request

Approved? (Condition)

Advise

Requester Declined

Advise

Requester Declined Back to flow

Back to flow

Advise

Requester Approved

Advise

Requester Approved Back to flow

Back to flow

Returned

Product

Returned

Product

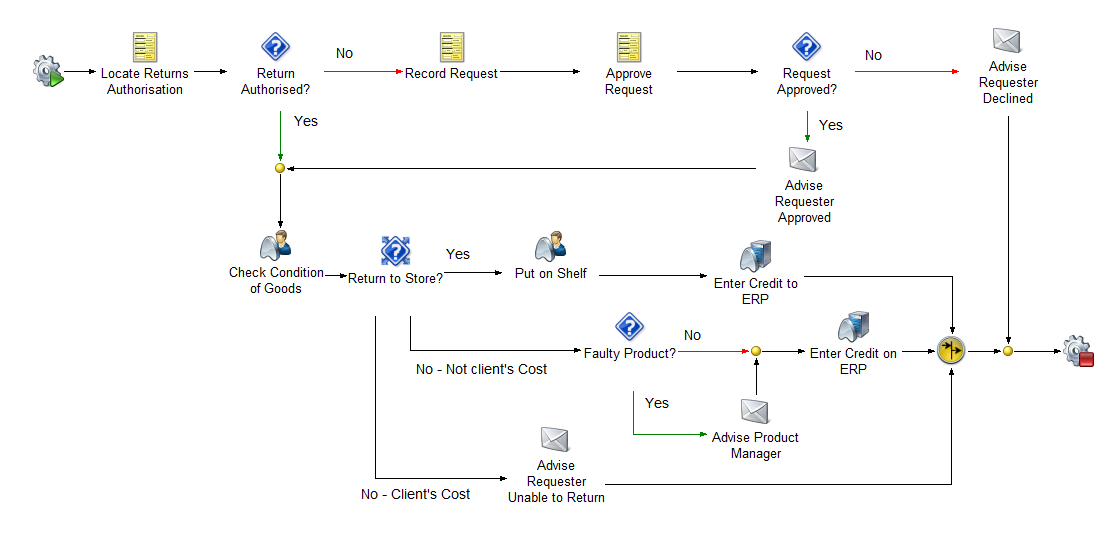

Overview:

Product may be returned for a number of reasons. It may be suitable for restocking.

A client may receive a credit for return. If the product is faulty and this is a

manufacturing or other factory fault, then the suppliers are advised.

10. Process: Returned Product

Who can start this process?

Warehouse

Manager

Warehouse

Manager

Warehouse

Staff

Warehouse

Staff

Overview:

Product may be returned for a number of reasons. It may be suitable for

restocking. A client may receive a credit for return. If the product is

faulty and this is a manufacturing or other factory fault, then the suppliers

are advised.

Locate

Returns Authorisation

Locate

Returns Authorisation Back to flow

Back to flow

Warehouse

Manager

Warehouse

Manager

Warehouse

Staff

Warehouse

Staff

Return

Authorised? (Condition)

Return

Authorised? (Condition)

Record

Request

Record

Request Back to flow

Back to flow

Warehouse

Manager

Warehouse

Manager

Warehouse

Staff

Warehouse

Staff

Return

of Goods Request(Worksheet)

Return

of Goods Request(Worksheet)

Procedure:

Enter all details relating to the request.

The more information available, the more likely the request will be approved.

The original sales order must be located and the order number entered.

Approve

Request

Approve

Request Back to flow

Back to flow

Management

Management

Warehouse

Manager

Warehouse

Manager

Approve

Request (Worksheet)

Approve

Request (Worksheet)

Procedure:

Review the information provided and either approve or decline.

Please add any comments and / or reasons for your approving / declining

the request.

Request

Approved? (Condition)

Request

Approved? (Condition)

Advise

Requester Declined

Advise

Requester Declined Back to flow

Back to flow

Check

Condition of Goods

Check

Condition of Goods Back to flow

Back to flow

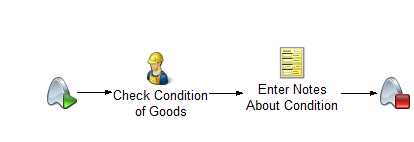

11. Process: Returned Product, Stage: Check Condition of Goods

Warehouse

Manager

Warehouse

Manager

Warehouse

Staff

Warehouse

Staff

Enter

Notes About Condition(Worksheet)

Enter

Notes About Condition(Worksheet)

Procedure:

Enter notes about the product condition. Record serial numbers (if

any) so that any patterns in faults found can be tracked better, allowing

better advice to the supplier.

Check

Condition of Goods (Manual)

Check

Condition of Goods (Manual)

Procedure:

Inspect all returned goods to ensure that seals (if applicable) are intact

and labelling is correct for the contents.

Batch numbers (if any) are recorded for future tracking of patterns

of faults, and advice to the factory.

Return

to Store? (Decision)

Return

to Store? (Decision)

Put

on Shelf

Put

on Shelf Back to flow

Back to flow

Warehouse

Manager

Warehouse

Manager

Warehouse

Staff

Warehouse

Staff

Put

on Shelf (Manual)

Put

on Shelf (Manual)

Advise

Requester Approved

Advise

Requester Approved Back to flow

Back to flow

Advise

Requester Unable to Return

Advise

Requester Unable to Return Back to flow

Back to flow

Enter

Credit on ERP

Enter

Credit on ERP Back to flow

Back to flow

Management

Management

Warehouse

Manager

Warehouse

Manager

Advise

Product Manager

Advise

Product Manager Back to flow

Back to flow

Advise

Warehouse Manager (Send Email)

Advise

Warehouse Manager (Send Email)

Procedure:

The Warehouse Manager is advised, with details of the client, order number,

order date and batch number (if any), so that product faults can be advised

to the supplier for correction.

Faulty

Product? (Condition)

Faulty

Product? (Condition)

Enter

Credit to ERP

Enter

Credit to ERP Back to flow

Back to flow

Management

Management

Warehouse

Manager

Warehouse

Manager