This was an adaptive controller in which a mathematical approach was taken to analyse the process' parameters in real time, then apply an adaptive correction to the dough's water content. The controller monitored the results of its corrections and “learned” from experience how to calculate the required correction - in effect a form of "artificial intelligence".

To build this controller, I was introduced to the operation and management of a modern bakery. As a result of implementing this system and the printed graphical reports it produced, the client (Quality Bakers) and I discovered the original cause of their consistency problems was due to seasonal and batch blending variations in the quality of flour delivered to the bakeries.

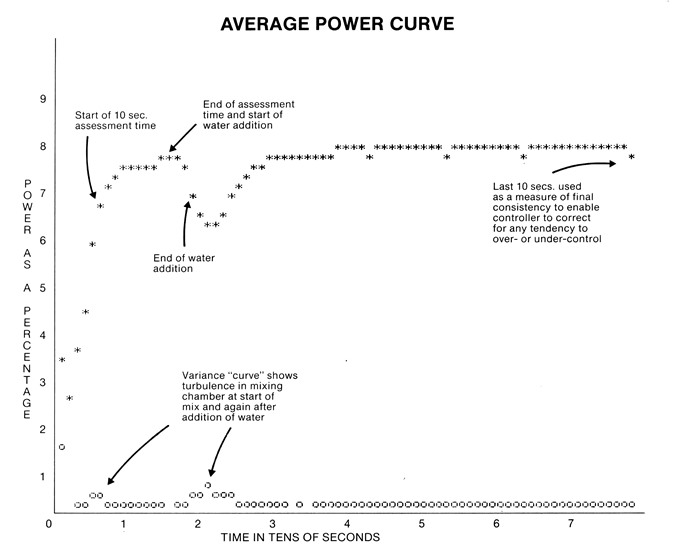

The amount of power required to drive the mixer was used as a direct measure of dough consistency. This then enabled a correction to be made by the addition of water during mixing to bring an intentionally "tight" dough to a satisfactory consistency with a closer, more reliable tolerance than had ever previously been achieved.

The controller would take a large number of readings (or samples) for mathematical analysis to determine the amount of additional water required to correct the consistency of the dough. This period was referred to as the assessment time. (See diagram below). At the end of this period, water was added and the controller then continued to take readings until the mixer stopped. These additional readings were then used to mathematically calculate any adjustments necessary to be made to the reference data stored in its memory. All relevant data derived was available for display (or print out) on command;